Above: Cranfield University is participating in an ATI-funded project that will develop novel digital twins to improve proactive planning

TRADITIONAL PRODUCT MANUFACTURING BUSINESSES ARE INCREASINGLY FOCUSING ON VALUE-CREATION CHAINS BY DEVELOPING EXTENDED SERVICE OFFERINGS THROUGHOUT THE LIFE OF THE PRODUCT. A NUMBER OF MANUFACTURERS IN THE AEROSPACE AND DEFENCE SECTOR ARE NOW GENERATING MORE THAN 50% OF THEIR REVENUE FROM SERVICE SUPPORT. SUCH OFFERINGS ARE PROMOTING NEWER PRODUCTSERVICE SYSTEMS (PSS) BUSINESS MODELS, WHERE THE PRODUCT ITSELF IS NO LONGER SOLD BUT ITS SERVICE OR PERFORMANCE IS.

The process of advancing from simplistic services to more advanced offerings is termed as ‘servitisation’ and there have already been several successful applications in the airline, railway, infrastructure, heavy equipment, car rental and white goods sectors. These range from providing very basic services such as installation, maintenance planning, take-back and recycling to the most advanced services that emphasise value derived from utilisation rather than the product itself.

Aerospace was among the first industries to embrace ‘total care’ solution packages.

Xerox international, for example, has offered a ‘pay per copy’ model where the customer only pays for the printed copies rather than the printer itself, and Rolls-Royce’s ‘Power by the hour’ service provides a ‘total care’ solution package where airline operators buy the engine capabilities rather than the engines. As a customer, the UK Ministry of Defence (MoD) values the move towards advanced services. In order to identify suitable contractual approaches, the MoD has developed the Support Options Matrix, a framework that supports the integration of services from their suppliers by defining and providing the rationale behind each type of contracting option.

In addition to this servitisation in high value product manufacturing organisations, there is also now an exciting shift towards through-life solutions in the machine tool sector. This is promoting the need to evaluate technology, skills and process-related maturity and also creating a need to explore alternative contracting approaches that will offer win-win scenarios across the supply network. Digital technologies that can provide up-to-date information and analysis about the health of the machine tools will become increasingly used and critical for the industry.

Intimate knowledge of the performance and life cycle of all components is essential in TES business models, which transfer in responsibility from the customer to the OEM or solution provider

The trend is likely to continue but at this point it is difficult to estimate to what extent. There are a number of challenges that may hinder the successful adoption of PSS in the machine tool sector and these are driven by uncertainties associated with both customer and manufacturer activities in the process of co-creation of value.

Challenges range from predicting and delivering equipment availability (which becomes a key element of the contract as a performance criterion) to human factors, uncertainties around the skillsets of maintainers, along with potential for skills obsolescence due to the longer timeframes involved.

One of the key uncertainties of this new business model is supplier dependence – with a transfer in responsibility from the customer to the original equipment manufacturer or solution provider, a strong and reliable supply network is critical. The performance of each supplier and how this affects the outcome of the system as a whole is a major source of uncertainty.

As the responsibility moves to the solution provider it becomes essential to have suitable processes to proactively fulfil demand. These processes involve planning for failure and delegation across the supply chain to manage impact. Suppliers become more integrated to the supply chain and central to achieving customer requirements.

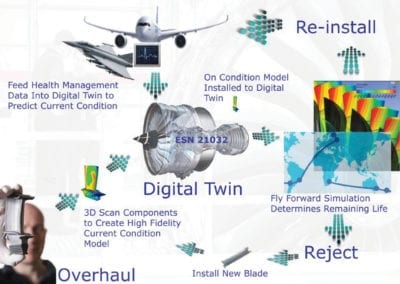

Technology can help in this and at Cranfield we are now participating in a new ATI-funded project looking into ways of using technology to improve throughlife service provision. The project will combine research physical degradation characterisation and real-time models to optimise the maintenance requirements through-life. Along these lines, novel digital twins will be developed to improve proactive planning. Digital twinning involves creating digital replicas of physical assets and processes and can assist with limiting uncertainty around equipment failures and improve planning for when replacements may be needed.

Overall, a more proactive approach is required to achieve various targets such as profitability, affordability and sustainability. This will be facilitated by better sharing of knowledge and information between customers and manufacturers in order to gain greater clarity around service requirements and needs in this new context for service delivery.

Dr John Erkoyuncu is a Senior Lecturer in Digital Service Engineering, Deputy-Director of the Through-life Engineering Services Centre and Course Director of the MSc in Through-life System Sustainment at Cranfield University.

THE SIZE OF THE PRIZE

Early adopters of TES (through-life engineering services/’servitisation’ in aerospace & defence have already demonstrate around:

- 20% reduction in cost

- 20% improvement in asset availability