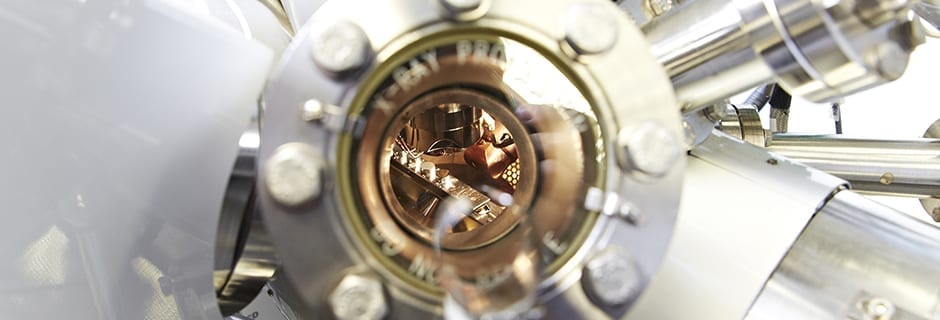

Above: BP’s Prosperity Partnership with the University of Manchester aims to understand and help prevent corrosion in critical applications

[title size=”4″]BP HAS BEEN INVESTING IN THE FIGHT AGAINST CORROSION FOR MANY YEARS. THE £2.6 MILLION PREVENTING SURFACE DEGRADATION IN DEMANDING ENVIRONMENTS PROSPERITY PARTNERSHIP, FUNDED BY THE EPSRC, INVOLVES BP, IMPERIAL COLLEGE LONDON AND THE UNIVERSITIES OF MANCHESTER, CAMBRIDGE, EDINBURGH AND LEEDS IN FUNDAMENTAL RESEARCH AND PRACTICAL APPLICATIONS[/title]

Some corrosion is helpful; aluminium oxide, for example, forms a protective external film that protects the pure metal underneath. Iron oxide – rust – on the other hand, forms a film that crumbles away and continually exposes fresh material. If not interrupted, entire structures will decay into dust. Thousands of miles of pipelines, for example, along with their ‘christmas trees’, valves, and control units, are at risk from corrosion. So, too, are wind turbines; by their very nature, they tend to be located in less hospitable environments, whether at sea or in upland regions. For BP, developing ways to inhibit corrosion supports its safety agenda and is commercially important.

[title size=”2″]Multi-million $ investment[/title]

Professor Phil Withers heads the Prosperity Partnership project between BP and the University of Manchester

“BP has made a $100 million investment and established the BP International Centre for Advanced Materials (BP-ICAM) to develop research into advanced materials,” said Professor Philip Withers, FREng FRS, Regius Professor of Materials at the School of Materials at The University of Manchester. He set up the Henry Moseley Manchester X-Ray Imaging Facility at Manchester and served as the inaugural director of the BP-ICAM between 2012 and 2017. As well as the Universities of Manchester, Cambridge and Imperial College, the University of Illinois at Urbana-Champaign is also involved.

Professor Withers’ research involves the application of advanced techniques to follow the behaviour of engineering and natural materials, in real time and in 3D.

“Manchester has probably the largest corrosion group in the country”

[title size=”2″]Fundamental understanding[/title]

“We are trying to understand the basic mechanisms that lead to corrosion and generate the ‘fi lm’, and explain why it breaks down in, for example, iron oxide,” he explained. There are diff erent types of corrosion, as well. “Pitting corrosion is the worst. Traditionally, it was relatively easy to deal with controlled, slow erosion; local corrosion is more dangerous because it’s highly concentrated; it can proceed and grow faster.” With thousands of miles of pipelines running through diff erent environments,

local conditions become very important to understand. “This Prosperity Partnership is bringing together people with the right experience to address these issues. Our challenges are: can we develop the right inhibitors? Can we develop coatings and oils that stabilise the material?” he said.

[title size=”2″]More than just power[/title]

The University of Manchester has a range of equipment and depth of expertise that made it the natural choice to lead the project on corrosion

Professor Withers and BP-ICAM have a strong track record. They have worked with BP to develop real insight into materials and how they behave in the environments they operate in. The government funding that the EPSRC is providing is essential to the project. It is enabling BP-ICAM to perform more targeted research that will allow BP to understand aspects of corrosion better than before, and eventually develop enduring strategies to counter corrosion

[title size=”2″]A powerful team[/title]

While lubricants and fuels help to clean engines internally, the BP-University of Manchester project is seeking ways of preventing corrosion occurring in the first place

Why was the University of Manchester selected? – “Manchester has probably the largest corrosion group in the country,” Professor Withers said. “We have a great deal of experience with electron microscopy and there is a lot of investment going on here as well, in the new Henry Royce Institute, for example. The University is leading projects in four areas: graphene and 2D materials; nuclear; biomedical; and materials in demanding environments, which this programme is involved with.” The partnership with BP has developed in a manner diff erent from the traditional industrial relationship. It mentors, it is actively involved and is very much more ‘hand in glove’. While BP is the lead industrial player, other companies will benefi t from it – as will the UK’s energy, wind, chemicals and materials processing infrastructure and operations.