The spectacular automation, scenery and sets for Olympic ceremonies, high-profile brand events or for television shows such as ITV’s The Voice and BBC’s Sports Personality of the Year all have something in common: Stage One; a specialist manufacturer, interpreter of ideas, innovative design development and producer of pavilions, stage sets, ceremonies and anything that needs a distinct or spectacular setting.

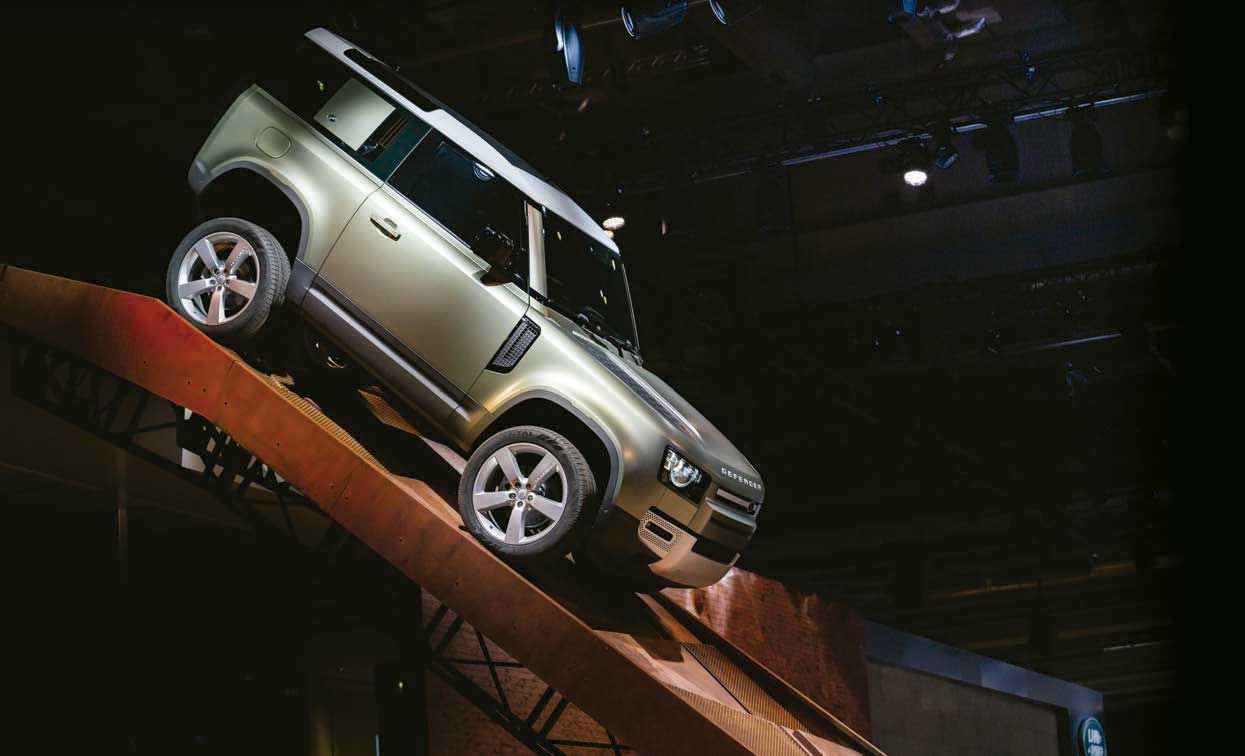

The company is headquartered in a 14,000sqm facility in Tockwith, near York. It has space and security to develop designs, build and secretly test complex sets, like the tilting wall that showed off the new Land-Rover Defender’s capabilities at its launch event at Frankfurt Motor Show.

Stage One also built the spectacular, two-storey pavilion for the BBC Studio stand at MIPCOM, Cannes, with its façade of 9250 precisely engineered and positioned aluminium discs, which limited glare from the Sun while allowing far-reaching views at eye level. After 18 months development, it was built on site in just six days.

Turning ideas into reality

“Projects rarely come to us in a production ready state” said Managing Director, Tim Leigh. “Every project we work on is unique and nearly all have to go through Design Development to work out the best methods for manufacture and installation.” Stage One uses Autodesk’s CAD software to make sure that every project they deliver meets or exceeds their client’s vision.

“With such a large capacity and with workshops across our site, we use the software to communicate to each department, the designer specifying different components, structures, materials and the particulars as to how each element should be made and built,” he explained.

Designs are tested virtually, within the computer, to ensure that everything fits, the right materials have been used and that loads won’t bring the whole thing crashing down. Approved designs are printed off and delivered to the appropriate workshop.

In addition to wood and metal work, construction itself can involve 3D printing/Additive Manufacturing, laser cutting and large volume 5-Axis CNC machining. Schedules can often be tight. The set used by American broadcasting company NBC for its NBCSN English Premier League coverage was designed, tested, built and installed in just two weeks from order.

“It’s not a production line; everything is bespoke,” Tim adds. “We work on and install projects across the globe. Detail is incredibly important so reliable software that ensures accuracy is essential.”