Autodesk: Future of British Manufacturing Initiative

Asif Moghal, Senior Industry Manager, Design & Manufacturing with Autodesk, the leading CAD CAM software company, introduces the Future of British Manufacturing Initiative and the companies that have been highlighted in this special section.

Automation has been at the heart of the success of UK manufacturing from the earliest days of the First Industrial Revolution.

As Industry 4.0, the Fourth Industrial Revolution, gathers pace, the importance of digitisation to the UK’s manufacturing industry cannot be overstated. It delivers increased efficiency, greater agility and the ability to win and retain profitable business in premium sectors, such as aerospace and automotive.

Digitisation is not just for large, multinational companies – indeed, it is SMEs that have the most to gain from it. Autodesk is committed to helping our clients and customers to grow and compete in the new, digitised world. As a company, we are proud to be sponsors of the Future of British Manufacturing Initiative (FoBMI).

The companies featured in the following pages give an insight into the way digitisation can be transformational, across a range of industries.

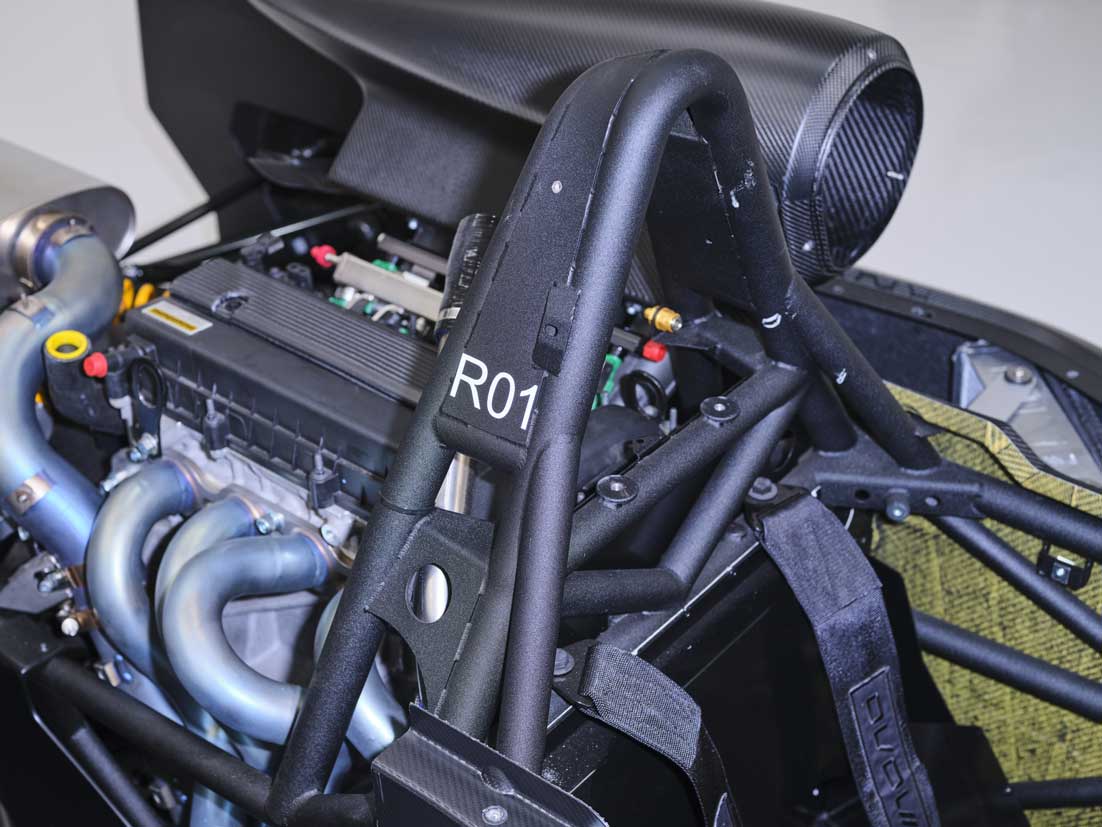

BAC (Briggs Automotive Company) uses a suite of software to develop one of the world’s fastest, leading edge cars. Its latest model is the first production vehicle to use graphene in its construction.

Hosokawa Micron was helped by Oliver Hopkinson as its Digital Catalyst to resolve problems it was having in implementing AR and enabled design and development time to be cut by weeks.

Kingspan’s IKON research hub uses advanced digital twin systems to demonstrate how real-time data from sensors enable building users to interrogate occupancy, CO2 levels, sound performance and structural values.

Lintott Control Systems has used commercially available software and in-house solutions to develop i-CatalystR digital delivery suite, which cuts development time from weeks to a matter of hours.

Mabey Bridge has automated part of the design process to create rules-driven, interactive 3D models more easily, and boost efficiencies across the business.

Stage One designs, build and virtually tests complex sets for Olympic ceremonies and TV spectaculars before delivering 3D printed, laser cut constructions.

Thermotex based its digital strategy on PLM, which enabled the capture of the company’s accumulated knowledge and provides accurate tracking and tracing through production.

Ultra Electronics has adopted additive manufacturing technologies to reduced lead time and cost, and greatly reduce wastage of expensive material.

Warren Services was helped by a digital catalyst to implement Lifecycle Management and save hours of unproductive time translating an array of CAD applications into a single, accessible resource.