There is no doubt that 2019 has seen a further significant shift underway in the technological transition in the automotive industry from internal combustion engine technology to electrification. This shift is both in terms of production but also consumer attitude and perception that we are moving in this direction. Tony Harper, Faraday Battery Challenge Director, UK Research and Innovation

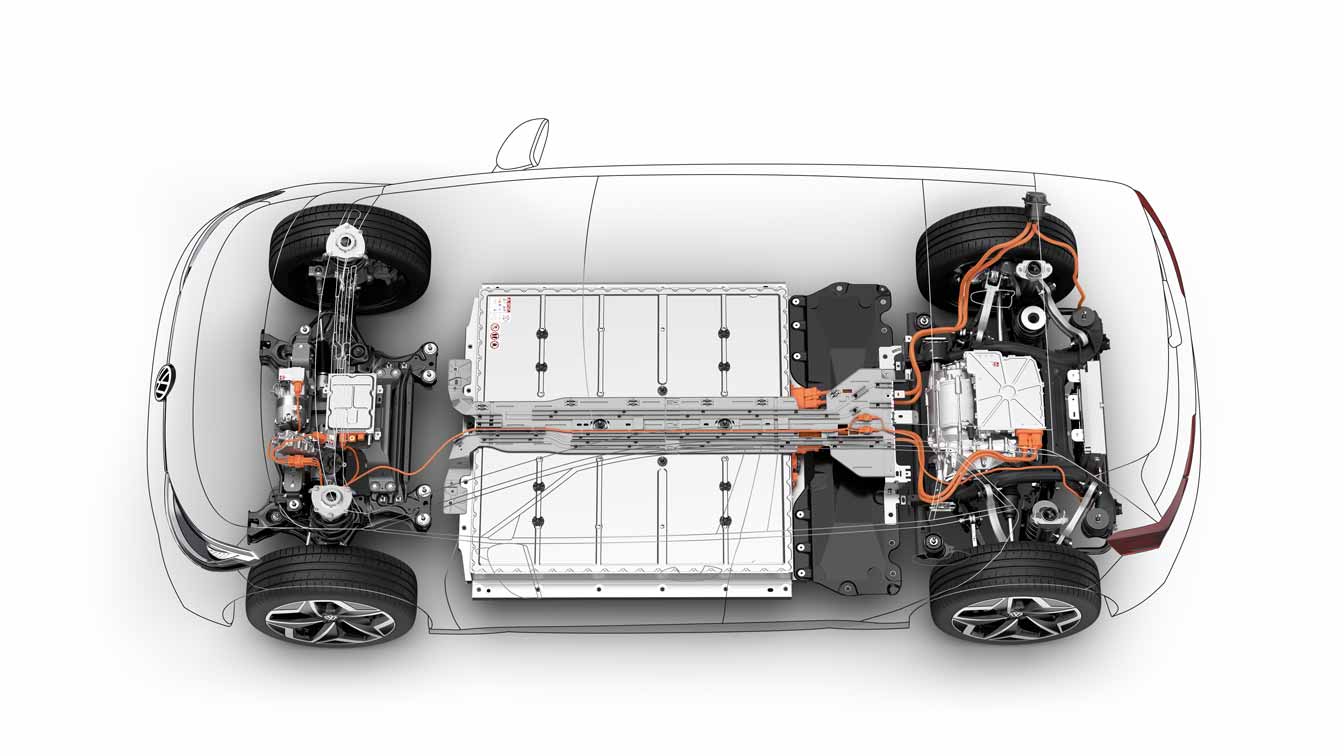

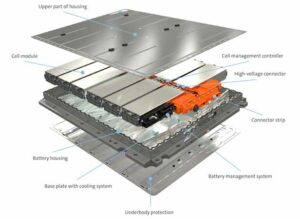

Structure of the MEB battery

We all know how important the automotive industry is to the UK, and how it is imperative to support the industry through the disruption caused by electrification. We need to drive hard now and invest heavily in the research, development and scale up activities to ensure the battery industry in the UK thrives.

In fact, a recent study by the Faraday Institution and produced with McKinsey Energy Insights and the University of Oxford predicts that by 2040 there will be demand for 8 gigafactories in the UK. But let’s think of things in a different way. In 2025 – a timescale over which many of us will have bought our next car – the report predicts the annual number of new EVs purchased to be approximately 750,000 cars. That’s 750,000 individual or family purchasing decisions.

One customer at a time It is imperative that we as an industry don’t forget that demand for EVs will be driven one consumer at a time. We need to examine the perceived barriers to EV adoption – whether we in the industry believe they are real or not.

To take one example, a recent Auto- Trader study report quotes 99.3% of all journeys made in the UK are with the average range of EVs. Yet the public worries about range.

Further, the gap between public perceptions and commonly held views of the industry may be increasing. There are a multitude of reasons – and surveys – on why individuals don’t buy EVs. But time and again common reasons quoted are: cost, range and charge points. These must be addressed.

The good news is that the Faraday Battery Challenge is addressing both technical and public concerns through our research agenda. The Challenge has a huge role to play in developing batteries that cost less, and can support longer EV range, but also increasingly playing a larger role in correcting misinformation and changing perceptions.

The Faraday Battery Challenge is structured around the following three strands of work:

- Fundamental research from the Faraday Institution

- Innovation -Collaborative R&D projects, co-funded with industry

- Scale up – UK Battery Industrialisation Centre – UKBIC

Fundamental research takes time but already after 16 months Faraday Institution funding has resulted in: two patent disclosures, with one to follow and another three or four in the pipeline; fellowship funding to three potential commercial spin outs; over 40 scientific publications – several in top tier journals and multiple industrial collaborations.

And in September the Faraday Institution has selected its new five project consortia in four research areas that it will fund to the tune of up to £55m.

All of these projects will conduct application- inspired research to make step changes in the understanding of battery chemistries, systems and manufacturing methods.

Collaborative research and development projects

Through the Faraday Battery Challenge UK businesses can access grants for feasibility studies and collaborative research and innovation projects that develop new and improved battery technologies that are more cost effective.

Projects to get funding so far include improving battery lifespan and range and the reuse, remanufacture and recycle of batteries at their end-of-life.

The figures on collaborative R&D are impressive – £114 million invested through government and industry funding in 62 projects.

The UK Battery Industrialisation Centre is set to open in 2020 in Coventry. UKBIC will offer industry, via open access, the opportunity to scale up and commercialise advanced technologies central to the development and manufacture of batteries, initially for the automotive sector but with wider application.

The UK Battery Industrialisation Centre is set to open in 2020.

This means, it will be working to perfect production of the next generation of battery systems across electrode, cell, module and pack levels to allow companies to move to full scale, high volume battery manufacturing (i.e. ‘Gigafactories’) and high volume electric vehicle production as subsequent investments.

Williams Advanced Engineering Launches New Battery Technology at Cenex LCV2019

But why the need for a UK-based gigafactory? The auto industry is a game of tight margins.

Batteries are bulky and expensive to ship and battery production – at cell, module and pack level – will need to be co-located with EV manufacturing.

This points to the imperative for a UK-based gigafactory. It is likely that, in order to meet the demand by 2025, the UK will need to attract large scale battery cell manufacturing investment from overseas, based on an iteration of known Lithium Ion Technology.

This along with a strong UK chemical supply chain, and indigenous OE demand, creates a demand-driven end to end value chain in the UK.

If you then combine with multi-fold growth beyond 2025, this creates the industrial backbone and market opportunity for a thriving UK intellectual and physical supply chain in new, breakthrough battery solutions at which the UK excels.

Faraday winners Round 2, Ilka Technologies. Left to Right. Dr Denis Pasero – Product Commercialisation Manager. Dr Louise Turner – Technical Officer. Graeme Purdy – Chief Executive Officer. Elaine Kent – Project Manager.

ILIKA TECHNOLOGIES: RECHARGING THE ELECTRIC VEHICLE MARKET

Lithium-ion batteries are the most widely used type of rechargeable battery in the world. This is largely down to their ability to produce a relatively high amount of energy and a reasonable cycle-life – the complete charge and discharge of a battery – of about 1,000.

Despite this, it’s believed that current lithium-ion batteries have almost reached their full potential. To encourage the adoption of electric vehicles, better, alternative solutions must be found.

“[With lithium-ion batteries] there will only be small increments in energy and power densities possible over the coming 10 years,” Dr Louise Turner, Technical Director at Ilika Technologies, explains But Ilika’s work in solid-state could see it produce batteries with double the energy density. “It’s widely accepted within the automotive industry that solid-state batteries will be a key enabler for the electrification of vehicles and their widespread uptake.”

Ilika is currently working on scaling up its solid-state battery technology in a project funded through the Industrial Strategy Challenge Fund’s Faraday battery challenge.

The challenge Ilika must overcome is ensuring the material is conductive enough within a car battery to provide the full suite of benefits, in particular, reducing the time it takes to charge the vehicle.

Ilika is working alongside a number of large companies as part of this research and development project. Collaborators include the Centre for Process Innovation, Honda, Ricardo and University College London (UCL).

Faraday Round Winners ICoNiChem pictured at International Automotive Research Centre Warwick University. L to R: Beth Middleton, Research Fellow, WMG. Dr Rob Sommerville, Project Engineer, WMG.Emma Kendrick, Reader, WMG. Paul Croft, Operations Director, Iconichem. Dr Vanessa Goodship, Principal Research Fellow, WMG.

ICONICHEM: RECYCLING RARE MATERIALS IN ELECTRIC VEHICLES

The electric vehicle industry is already growing rapidly, and with the UK government’s plan to end the sale of new conventional petrol and diesel cars by 2040, the market is only set to grow.

In turn, demand for critical elements such as cobalt, nickel, manganese, lithium and graphite, commonly used in the production of electric vehicle batteries, will also rise.

Cobalt salts producer, ICoNiChem Widnes, is leading a project to embed recycling and reuse of materials in the electric vehicle supply chain – and tackle some of the problems associated with the sourcing and use of these elements.

“We believe the UK needs to move towards a circular economy to fully realise the green ambitions of electric vehicles,” says Paul Croft, Operations Director at ICoNiChem. The circular economy puts recycling and remanufacture at the centre of production, minimising waste and putting materials back into the supply chain. “Batteries don’t last forever, and with a lifetime of 8 to 10 years, there will be a lot of waste developed. If we don’t, as a country, consider what to do with that waste, then [electric vehicles] won’t be as green as we think.”

ICoNiChem is working alongside research organisation Warwick Manufacturing Group (WMG), and others, in a recycling and reuse project through the Faraday battery challenge.