Surface Engineering & Precision Institute

The future in Materials and Manufacturing is where science, technology and design collide. Cranfield’s Surface Engineering and Precision Institute (SEPi) is a world-leading centre that brings together scientific and engineering disciplines, integrating materials characterisation, design and manufacturing expertise to enable the manufacture of future smart systems, sensors and coatings through the discovery/development of materials with purpose-built properties.

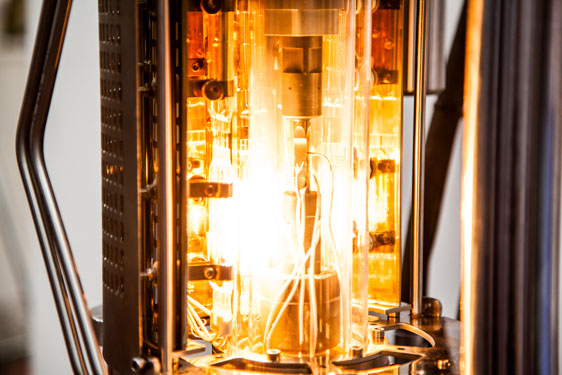

Example of a specimen under test under an extreme environment containing flowing SO2 and salt.

The Surface Engineering and Precision institute (SEPi) at Cranfield University is an internationally recognised centre of excellence in material research and development. Its research covers two main specialisms: Coating/Surface Engineering and Device/Smart Materials; both aiming to undertake world-leading research in the areas of materials engineering and functional materials.

Each specialism is supported through distinct organisational structures based on research groups with particular disciplinary expertise (e.g. polymers, nanotechnology), and research themes (e.g. biomedical, high temperature corrosion and protection), which facilitate cross-disciplinary interaction between groups, other schools, research institutes in the University, and external organisations.

These cross-domain groups deliver on our strategy of opening the door to new technologies, whether they are in sustainable, aeronautical, biomedical, or sensor engineering. SEPi’s vision is supported by fundamental and applied research that aims at addressing challenging material engineering problems facing the world and providing translational and sustainable solutions as explained by Dr. Gregory Bizarri, acting Head of the centre.

Phosphorescent Thermal Barrier Coatings (TBC) on a turbine component enabling multiple sensing capabilities

Surface coatings

“Our main research activities relate to the design and manufacture of protective coatings to allow engineering systems to operate in harsher and more demanding environments. Here, research is focused on the design and manufacture of Thermal Barrier Coatings, High temperature corrosion resistant coatings and the development of in-situ diagnostics (Smart Coatings), as well as and the design of surface engineering solutions at the systems level,” he says.

High Temperature Corrosion and Mechanical Interactions

“Our approach encompasses the assessment of materials performance in a variety of aggressive environments from all aspects of industry from the aero-gas turbine to boiler plant to concentrating solar power plant. Not only do we offer a testing solution, within the centre we are able to offer solutions to engineer materials performance through in-house coating solutions.”

Sensors and devices

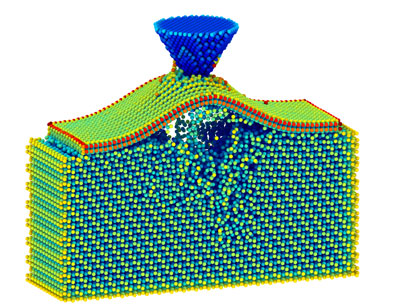

“Our research focuses on providing solutions for sensing devices, functional materials and their integration at system level. We have a speciality in advanced functional materials such as piezoelectric, pyrolelectric, thermoelectric, catalytic, luminescence, radiation detectors and biosensors working at the nano to micro and macro scales. This effort greatly benefits from our expertise in ultra-precision engineering that allows rapid and fine feature generation processes for multi-scale processing and effective quality control.”

Recent achievements at SEPi

Molecular dynamics showing delamination of a carbon coating probed by nano-indentation.

- Growing, sustainable and diversified research income. A portfolio of UKRI, EU and charitable funding supports fundamental research that advances the intellectual boundaries of our engineering disciplines. Our research reputation attracts industrial sponsors with industrial research funding forming a significant proportion of our research income.

- Conduct internationally recognized research to provide the fundamental and technical knowledge that underpins technological innovation.

- Extension of our world leading technical facilities such as i) National High Temperature Surface Engineering Centre (NHTSEC) and ii) Ultra Precision Machining Centre.

- Increasing our research student numbers currently amounts to 26 with support coming from diverse sources (Research Councils, Industry, self-funded, Overseas Governments)

www.cranfield.ac.uk/centres/surfaceengineering- and-precision-institute