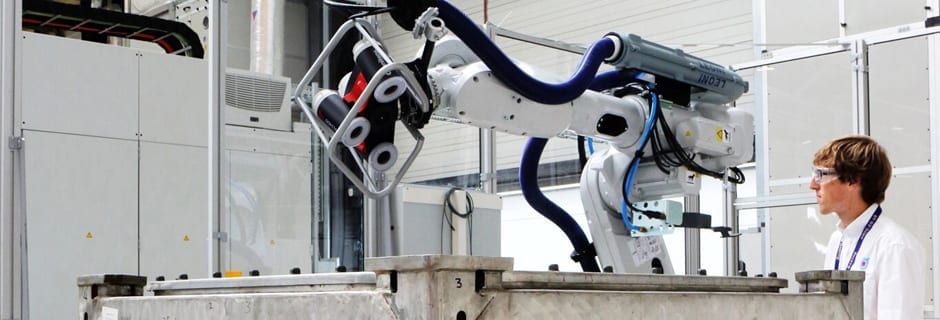

Above: The Nuclear AMRC is expanding support for UK Manufacturers seeking to win work in the sector

[title size=”4″]With the UK’s nuclear new build programme finally getting underway at Hinkley Point C, and growing interest in a new generation of advanced modular reactors, the Nuclear AMRC is expanding its support for UK manufacturers who want to win work in the sector.[/title]

- The Nuclear AMRC is focused on large-scale quality-critical manufacturing

- Its South Yorkshire facility has £30 million of state-of-the-art manufacturing equipment available for collaborative use

- It is working with key partners to improve manufacturing efficiency and reduce risk for nuclear new build and decommissioning

- Nuclear AMRC engineers are working with Sellafield Ltd to improve manufacturing methods for the standard 3m3 waste container

- “Modular manufacture… is key to the delivery of a new generation of advanced reactors of all sizes” [/content_box]

[/content_boxes]

[title size=”2″]Safety critical[/title]

The centre is also expanding its capabilities in equipment qualification (EQ), a systematic approach to ensuring that safety-critical components for new nuclear power stations meet quality standards. The Nuclear AMRC is working with industry partners to ensure that UK manufacturers are ready to meet EQ requirements, reducing the risks of new build while maximising the opportunities for the UK supply chain.

Supply chain development is a critical issue for the nuclear industry, and the Nuclear AMRC is playing a key role in ensuring that UK suppliers can compete in a global market. The centre works with individual companies to help them meet and exceed nuclear buyer requirements, and is working with the global reactor developers to build a UK supply chain for their specific needs.

The centre’s flagship Fit For Nuclear (F4N) programme has become an industry benchmark for nuclear-ready manufacturers. More than 130 companies have been granted F4N status following a rigorous assessment and business improvement process. Recently granted companies range from specialist heat exchanger manufacturer Heatric, part of the global Meggitt group; to Barrnon, a tiny Cumbrian firm moving from fishing into nuclear decommissioning.

[testimonials backgroundcolor=”” textcolor=””]

[/testimonials]

[title size=”2″]Supply chain development[/title]

The Nuclear AMRC has also delivered a significant boost to key suppliers through the Civil Nuclear Sharing in Growth (CNSIG) programme. CNSIG provided a four-year programme of intensive business development to an initial 10 companies, supported by £1 million match-funding each from the Regional Growth Fund. To June 2017 (with six months of the programme still to run), the participating companies have reported that CNSIG has helped them secure around £455 million of orders, creating or safeguarding 5,440 jobs, and have committed an additional £49.2 million private investment.

The Nuclear AMRC continues to enhance and expand its supply chain development programme to meet industry demand. F4N now offers additional targeted support to companies after granting, and the team are now applying the knowledge they gained through CNSIG to develop new services and add more value to UK industry.

[testimonials backgroundcolor=”” textcolor=””]

[/testimonials]

Uniquely, the Nuclear AMRC offers an integrated package of supplier development and manufacturing innovation, helping UK manufacturers of all sizes raise quality, reduce costs, develop new technical capabilities, and meet the demands of the nuclear sector. 2018 will bring additional R&D capabilities, including the UK’s most powerful disk laser facility; new regional hubs, to help the centre work more closely with regional supply chains at key nuclear sites around the country; and more support for manufacturers in areas such as electrical control and instrumentation.

This is a crucial time for the UK nuclear industry, and the Nuclear AMRC is ready to help manufacturers along the supply chain to compete and win.